World leader in thermal solutions

Play Video

Discover our video Play Video

World leader in thermal solutions

FIB GroupEngineering office specialized in thermal and chemical treatments, surface coating, and tailor-made equipment manufacturing for the steel wire, glass, and piece galvanizing sectors.

FIB GROUP, active since 1936, designs and manufactures industrial furnaces, equipment, and heating solutions for production lines in the steel wire, glass, and piece galvanizing sectors.

FIB GROUP has offices and workshops across Europe, with over thirty specialized engineers. Recognized globally as an integrator, FIB GROUP ensures manufacturing, assembly, and maintenance services in over 60 countries across all five continents.

Technical solutionsExpert in tailor-made

equipment and accessories

Steel

Wire

Design and manufacture of production lines and equipment for steel wire production

- High carbon line

- Low carbon line

- Spring/suspension wire line

- Stainless steel wire furnace

- Bell furnace

- Pit furnace

Hollow glass-foam

glass

Design and manufacture of industrial combustion equipment and critical parts for manufacturers of hollow glass or foam glass production lines.

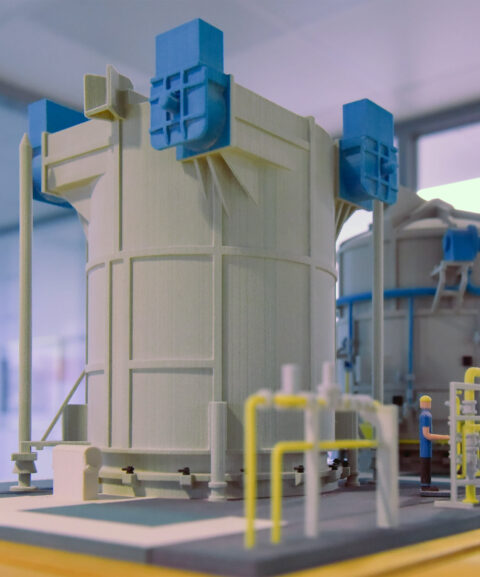

Piece

Galvanizing

Design and manufacturing of metallic galvanizing furnaces for steel structures and chain as well as ceramic furnaces for small metallic parts.

ServicesDiscover the comprehensive services

of FIB GROUP

0

Number of countries

0

Number of clients

0

Number of years of expertise

Innovation

Continuously innovating in the fields of thermal, chemical, and surface coating, FIB Group designs environmental friendly production lines.

FIB 4.0 installations are also equipped with digital solutions that provide tele-diagnosis and remote maintenance functions.

- Production costs

- Environmental impact

- Production quality

- Quality control

- Product traceability

- Safety

- Compliance with current and future country standards